In today’s hardware world, speed makes the difference between a product that wins and one that falls behind. Rapid PCB manufacturing enables engineers to move from design to tested hardware in just a few days rather than weeks. Whether you’re validating a new IoT device, updating a control board, or testing a startup prototype, fast and reliable PCB builds reduce iteration time, lower development risk, and keep your team’s momentum strong.

What Is Rapid PCB Prototyping?

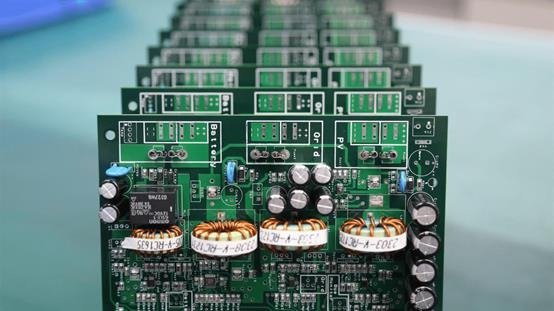

Rapid PCB prototyping means producing circuit boards in hours or a few days rather than weeks. It is used during early engineering validation (EVT/DVT) stages to check design, layout, and functionality before committing to full production. Traditional fabrication can take 2–4 weeks, while rapid services deliver 2–4-layer boards within 24–72 hours when design files and materials are ready.

Typical quantities range from five to a few hundred pieces. The goal is not large volume, but quick, high-quality samples that let you test and adjust your design confidently.

A Practical Workflow for Rapid Builds

To achieve short turn times, every step must be optimized. Here’s how a complete rapid pcb manufacturing process usually works:

- Data Preparation – Submit complete design files: Gerber or ODB++, BOM in Excel, XY pick-and-place file, and assembly drawings.

- Engineering & DFM Review – The manufacturer reviews your design for manufacturability, including impedance targets, minimum trace width and spacing, via sizes, copper thickness, and stack-up symmetry.

- Material & Process Selection – Standard FR-4 or high-speed materials are chosen with ENIG or OSP finish. Controlled impedance and precise drilling are handled upfront.

- Fabrication & Panelization – Drilling, plating, lamination, and routing are scheduled in parallel to shorten turnaround time.

- SMT Assembly & Inspection – Components are placed by pick-and-place machines, then soldered through reflow. Advanced AOI and X-ray systems verify fine-pitch BGAs and hidden joints.

- Testing & Delivery – Each board passes functional or visual checks before shipping via express couriers worldwide.

Learn more about rapid pcb manufacturing and see how modern facilities deliver consistent results under tight deadlines.

Design Rules That Actually Speed You Up

Design choices strongly affect how fast your boards can be produced. Following standard capabilities avoids unnecessary delays.

- Use standard layer stack-ups and copper thicknesses whenever possible.

- Keep minimum trace/space within your fabricator’s limits and reduce blind/buried vias.

- Maintain consistent impedance and plane references.

- Use clean rectangular panels with tooling holes and fiducials.

- Keep your BOM and silkscreen labels synchronized with component footprints.

Manufacturers like FastTurn PCB follow the IPC-A-600/610 and ISO 9001 standards, ensuring reliability and repeatability while maintaining RoHS and REACH compliance.

How Fast Is “Fast”?

Speed depends on your design complexity and the completeness of your documentation.

- 24–72 hours – Two- to four-layer boards with standard materials and a ready BOM.

- 3–5 days – Six- to eight-layer controlled impedance boards or partial component sourcing.

- 5–7+ days – HDI, rigid-flex, or specialty finishes that require additional process time.

A rapid manufacturer can often assemble PCBs within 8–72 hours once all materials are in-house. Planning for BOM readiness is key to meeting these tight schedules.

Capabilities That Unlock True “Rapid”

Modern facilities offer full flexibility between prototype and small-batch builds:

- Support for BGA, QFN, LGA, and fine-pitch FPGA packages (down to 0.3 mm).

- Mixed lead and lead-free solder processes with reflow and wave soldering.

- Automated X-Ray inspection for hidden joints.

- Production range from 5 to 100,000 pieces without switching vendors.

- Global shipping through FedEx, DHL, or UPS with online tracking.

From Prototype to Pilot Run

A key advantage of working with a single vendor is process continuity. The same design rules, tooling, and testing setups used for your prototype can be directly extended to pilot and pre-production builds.

Full or partial BOM management options simplify procurement. Manufacturers keep alternate parts and lifecycle data (PCN/EOL) on file to prevent supply delays. Automated testing methods like AOI and functional verification scale seamlessly from prototypes to small-batch runs.

Common Pitfalls That Slow “Rapid” Projects

Even the best production line can’t save an incomplete data package. The most frequent causes of delay include:

- Missing or mismatched BOMs, pick-and-place files, or drawing files.

- Nonstandard stack-ups or via structures requiring new tooling.

- Unusual board shapes or solder mask openings that prevent efficient panelization.

- Late component sourcing or unavailable parts.

Avoiding these problems means reviewing files early and sticking to standard manufacturing windows.

Quick Checklist Before You Click “Order”

Before placing your next rapid order, confirm the essentials:

- The Gerber or ODB++ file set is complete and consistent.

- BOM and assembly drawings match.

- Controlled impedance requirements are defined.

- Alternative components are listed for critical parts.

- Test points are available for inspection.

- Panelization and fiducials are ready.

- The chosen solder type (lead/lead-free) is marked.

- BOM is fully kitted if you expect 8–72h assembly.

FAQs

Q: What is rapid PCB prototyping?

A: It’s a manufacturing process that produces ready-to-test PCBs within hours or a few days, depending on design and material readiness.

Q: Do manufacturers ship worldwide?

A: Most do, including options through FedEx, DHL, and UPS with real-time tracking.

Get Your Next Build Moving

When time matters, a streamlined partner can make all the difference. Upload your Gerber, BOM, and pick-and-place files to get an instant quote and estimated turnaround. Work with FastTurn PCB — a proven expert in rapid PCB manufacturing, fast assembly, and global delivery. With full DFM review, IPC-certified quality, and reliable communication, your next prototype will be ready before you expect it.