Fuel nozzles may not be substantial entities in a turbine, but they are the first step in defining everything that occurs in the combustor (to the turbine’s performance). When the fuel nozzle meters, atomizes and distributes fuel, with consistency and accuracy; the turbine lights off “clean”, operates at intended efficiency, and emissions goals are met. When it is not performing; operators have to deal with potential range issues (flames being unstable, increasing emissions, unplanned trips, and high cost). Check this page to learn more.

What Role Do Fuel Nozzles Play in Combustion?

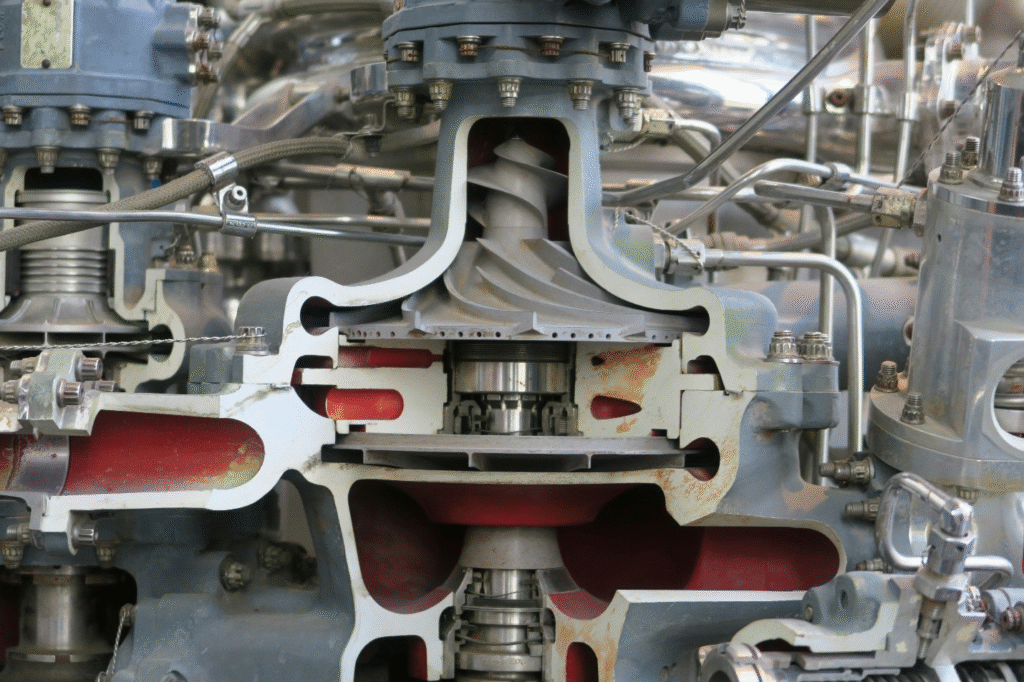

The nozzle is what establishes the quality of the mixture in a gas turbine. It meters the fuel flow, atomizes liquid fuel into droplets, and distributes the spray to make sure it mixes properly with compressor discharge air. Good atomization minimizes large liquid fuel droplets that have a slow combustion time, and good spray distribution provides an even steam distribution which prevents potential damage (hot spots) to combustor liners and turbine blades.

Today’s fuel nozzles, rely on geometry (swirlers, orifices, staging circuits) to provide the correct conditions to match the expected load. Dry low NOx systems rely on good mixture uniformity and stable flames as poor nozzle health may hinder DLN tuning resulting in a wider window of operations for CO or dynamics. Maintenance personnel often try to overcompensate a poor/low atomization quality by either spray pattern testing or a calibratable flow bench to verify metering accuracy. Understand these basic components is imperative to establishing a stable flame, at a cool combustor, and also protect downstream equipment.

Common Signs of Nozzle Wear

There is no doubt about it; temperature cycling, coking and tip erosion would advance the degradation of nozzle function. Fuel spray histories that are exposed to extreme temperature, and durations will diminish the burning edges from melting and/or deformation, restrict the material flow which enlarges the droplets. Most of the early indicators appear as changes in trending data or gradual shifts, not failed systems or sudden catastrophes, and that’s exactly why trending data and boroscope inspection data are valuable.

- Increasing exhaust temperature variation between cylinders or cans with essentially the same load

- Combustion dynamics alarms, rumble or unstable flame on transients

- Increased fuel flow to produce the same MW output, meaning poor atomization

- Repeated hard starts, flameouts or delayed light-off after maintenance

- Excessive coking on tips, damaged swirlers, or leaking seals found through inspection

Impact on Emissions and Efficiency

Nozzle wear typically adds to CO and NOx. Poor atomization results in unburned hydrocarbons and carbon monoxide in the exhaust at less than load, while poor and uneven fuel distribution results in local hot spots which drive thermal NOx when running at base load. The net effect is higher heat rate, more difficult baseline emissions compliance, and more frequent tuning changes. This is often at the point where shops recommend doing a fuel nozzle repair along with combustor cleanup, so as to return the hot section to native spray quality and flow balance. When the spray is right, the combustor burns better, and the turbine makes the same power with less fuel, which further widens emissions margin.

Preventive Inspection Practices

A structured preventive inspection program is going to find nozzle problems before they cause you to derate, or trip. Teams combine on-turbine inspections and checks with shop inspections and tests, to view outward condition and provide critical data to turn into the correct condition in the flow. Normally, the events that would trigger visits would align with minor outages, seasonal fuel or oil changes, or any time emissions margins start to tighten.

- Develop a baseline against the flow bench, with calibrations and allowable tolerances against each with each circuit

- Perform tests for spray pattern to verify droplet size and cone angle in accordance with cleaning or part replacement

- Use boroscope inspections when units are at outage to identify coking, cracked tips or swirlers wear without taking the assembly completely apart

- Clean and de-coke using approved methods; also replace seals and O-rings and confirm leak-tight reassembly

- Trend the spread exhaust temperature, fuel split and dynamics data to gate inspections if limits are known

Extending Turbine Life Through Nozzle Care

In combination, healthy nozzles protect the entire hot section. Even burn mixing eliminates local over-temperature and to the greatest extent possible reduces any oxidation and thermal fatigue in the combustor liners, transition pieces (dome); and first stage buckets. In addition to providing greater time outside of typical maintenance intervals, or, while still in service well beyond anticipated service intervals but still with observable function.

In addition to prolonging life of turbine components, nozzle care is also about operability. Better light-off; better and smoother load changes; and predictably accurate emissions compliance all bring speed in tuning, to reduce start-up fuel burn. Whether the fleet is running on natural gas, distillate, or dual-fuel, disciplined and careful nozzle maintenance—with good fuel filtration and good purge practice—keeps the machine operating their designed window. Effectively, looking after those most trivial metering orifice returns you benefits in reliability, efficiency, and lifecycle cost.